In the realm of modern plumbing and infrastructure development, selecting the right material for water supply systems is crucial. High - Density Polyethylene (HDPE) pipes have emerged as a leading choice for numerous applications, including water supply systems. This article delves into the viability of using HDPE pipes for water supply, exploring their benefits, applications, and comparisons with other materials. By analyzing the offerings from Akan Enterprise Group (Shanghai) Co., Ltd., a prominent manufacturer and supplier of HDPE pipes, we will provide a comprehensive understanding of why HDPE pipes are an excellent choice for water supply systems.

Can We Use HDPE Pipe for Water Supply?

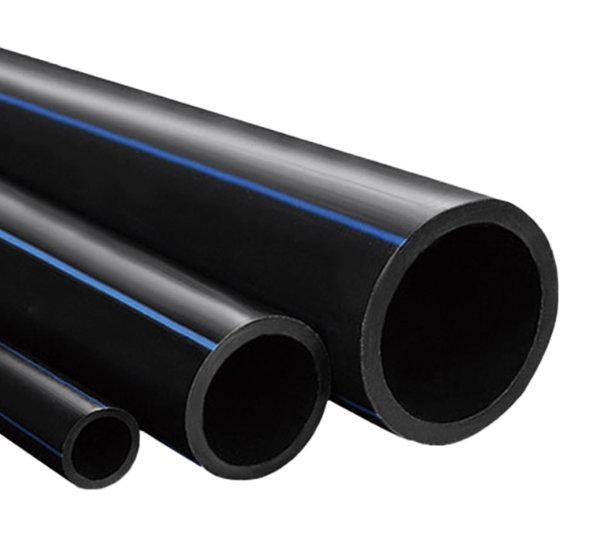

HDPE pipes are constructed from high - density polyethylene resin, a durable and flexible material known for its exceptional resistance to corrosion and environmental stress. These pipes are engineered to provide seamless, leak - proof connections through advanced heat fusion methods, ensuring long - term reliability and minimal maintenance. HDPE pipes are widely used in various industries due to their versatility, durability, and cost - efficiency.

Can we use HDPE pipes for water supply? The short answer is yes, and increasingly, municipalities, contractors, and water utilities worldwide are transitioning to HDPE pipes for water distribution projects. This shift is driven by the numerous benefits HDPE pipes offer over traditional materials like PVC, steel, and concrete. These benefits include superior durability, corrosion resistance, flexibility, and ease of installation, all of which contribute to long - term cost savings and environmental sustainability.

Akan Enterprise Group (Shanghai) Co., Ltd. is a leading provider of HDPE pipes, offering a comprehensive range of products designed to meet the evolving demands of modern infrastructure projects. Our HDPE pipes are manufactured to stringent quality standards, ensuring they are suitable for applications ranging from municipal water supply to industrial processes.

Benefits of Using HDPE Pipes for Water Supply

Durability

One of the most significant advantages of HDPE pipes is their remarkable durability and long operational life. Properly installed HDPE pipes can last up to 50 years, significantly outperforming traditional materials like PVC and steel. This longevity is attributed to their molecular structure, which resists abrasion, UV degradation, and general wear and tear. As a result, HDPE pipes offer a cost - effective and sustainable solution for long - term water supply systems.

Flexibility and Ease of Installation

HDPE pipes are highly flexible. This flexibility significantly reduces the need for additional fittings in curved installations, simplifying the overall construction process. HDPE pipes are also lightweight, making them easier to transport, handle, and install compared to traditional materials like steel or concrete. Their lightweight nature means that they can be more easily lifted and maneuvered by construction crews, reducing the need for heavy machinery and lowering overall installation costs.

Environmental Sustainability

HDPE pipes are an environmentally friendly option for several reasons. They are 100% recyclable, reducing waste and promoting sustainability. Additionally, HDPE pipes do not leach toxic substances into the soil or water, ensuring environmental safety and compliance with environmental regulations. The manufacturing and installation processes for HDPE pipes generally have a lower carbon footprint compared to materials like steel or concrete, making them a responsible choice for modern infrastructure projects.

Applications of HDPE Pipes in Water Supply Systems

Municipal Water Supply

HDPE pipes are extensively used in municipal water supply systems due to their ability to provide a safe and efficient water distribution network. Their corrosion resistance and long lifespan ensure that water supply systems remain functional for decades with minimal maintenance. HDPE pipes are also ideal for replacing aging iron and concrete pipelines, which are prone to corrosion, leaks, and high maintenance costs. By transitioning to HDPE pipes, municipalities can reduce water loss and improve overall system efficiency.

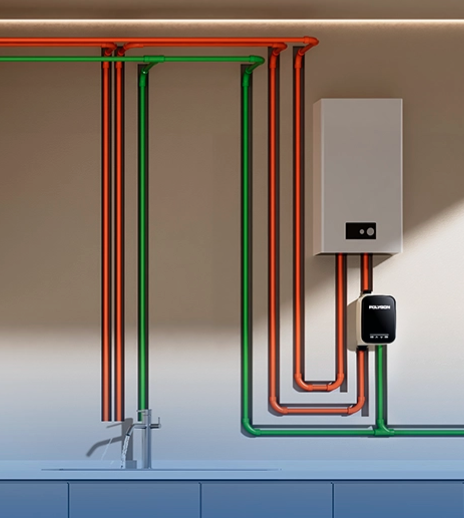

Residential and Commercial Water Supply

HDPE pipes are suitable for residential and commercial water supply systems, providing a reliable and efficient solution for transporting potable water. Their flexibility and ease of installation make them ideal for new construction projects as well as retrofitting existing systems. HDPE pipes ensure that water quality is maintained without leaching harmful substances, providing a safe and healthy water supply for households and businesses.

Industrial Water Supply

In industrial settings, HDPE pipes are used for transporting process water, cooling water, and other fluids. Their resistance to chemicals and environmental stress makes them suitable for handling a wide range of industrial fluids. HDPE pipes can withstand high - pressure conditions and provide seamless, leak - proof connections, ensuring efficient fluid transfer and reducing maintenance costs.

Comparison with Other Pipe Materials

HDPE vs. PVC

Although both HDPE and PVC pipes have good corrosion resistance, HDPE pipes have the following advantages:

1. HDPE has excellent flexibility and impact resistance, can withstand ground subsidence and freezing expansion, and is particularly suitable for geologically unstable areas or occasions where bending and laying are required.

2. HDPE has excellent low-temperature toughness, which can reach -40℃ at low temperatures, and can still maintain good flexibility and impact resistance, and is not easy to crack, making it an ideal choice for cold areas.

The connection is more reliable, and the hot-melt connection forms a seamless integrated pipeline system. The joint strength is higher than the pipe body itself, eliminating the risk of joint leakage. PVC is connected with glue, which contains various organic solvents and is not environmentally friendly.

HDPE vs. Steel

Steel pipes are known for their strength and durability, but they are also prone to corrosion and have a shorter lifespan compared to HDPE pipes. HDPE pipes offer excellent corrosion resistance and do not require additional coatings or treatments to prevent rust. This makes them a more cost - effective and sustainable solution for water supply systems. Additionally, HDPE pipes are lighter and easier to install than steel pipes, reducing labor costs and installation time. HDPE pipes also have lower maintenance requirements and a lower environmental impact compared to steel pipes.

HDPE vs. Concrete

Concrete pipes are commonly used in large - diameter applications due to their strength and durability. However, they are very heavy and difficult to install, requiring heavy machinery and significant labor. HDPE pipes, in contrast, are lightweight and flexible, making them easier to handle and install. HDPE pipes also have a longer lifespan than concrete pipes, which can be susceptible to degradation over time. Additionally, HDPE pipes have lower maintenance requirements and a lower environmental impact compared to concrete pipes.

Latest Trends and Innovations in HDPE Pipe Technology

The use of HDPE pipes for water supply systems is supported by ongoing advancements in material science and manufacturing technology. Some of the latest trends and innovations in HDPE pipe technology include:

Enhanced Manufacturing Processes

Akan Enterprise Group (Shanghai) Co., Ltd. employs advanced manufacturing processes to produce HDPE pipes that meet the highest quality standards. These processes ensure that the pipes have uniform wall thickness, smooth interior surfaces, and seamless connections. The use of state - of - the - art extrusion technology and quality control measures guarantees that each pipe is manufactured to precise specifications, providing reliable performance in water supply systems.

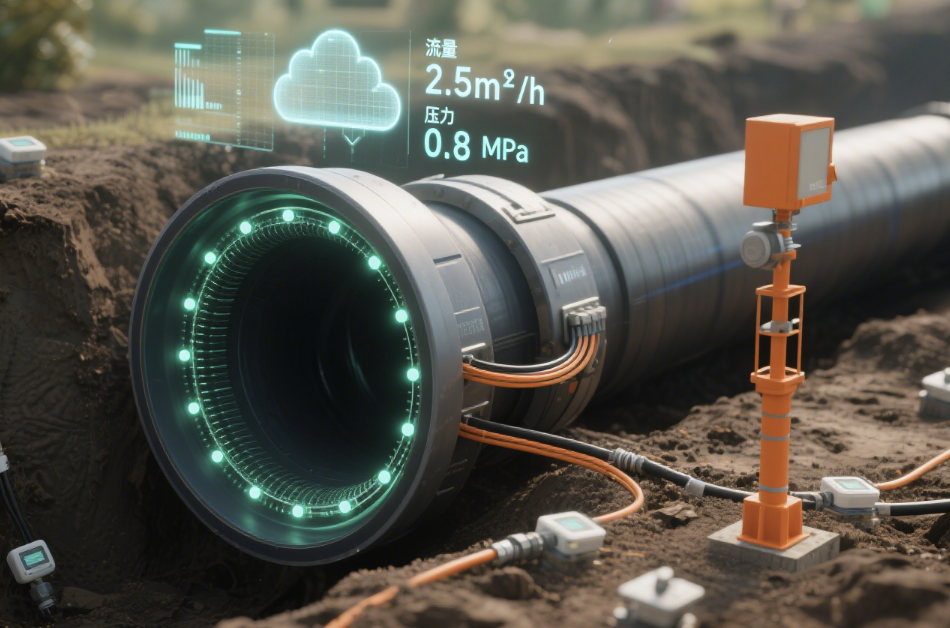

Smart Pipe Systems

With the increasing demand for smart infrastructure, HDPE pipes are being integrated with advanced monitoring and control systems. These smart pipe systems incorporate sensors and communication technologies to provide real - time data on water flow, pressure, and quality. This information can be used to optimize water distribution, detect leaks, and prevent system failures. Smart HDPE pipes offer enhanced reliability and efficiency, making them an ideal choice for modern water supply systems.

Sustainable Development

The focus on sustainability is driving innovation in HDPE pipe technology. Manufacturers like Akan Enterprise Group are developing HDPE pipes with improved recyclability and lower environmental impact. HDPE pipes comply with EN ISO 9080 international standards, PE100+ international certification requirements, and meet US PE 4710 standards. Additionally, the manufacturing processes are designed to minimize energy consumption and waste, aligning with global sustainability goals.

Case Studies and Real - World Applications

To further illustrate the benefits of using HDPE pipes for water supply systems, let’s explore some real - world applications and case studies.

Municipal Water Supply Project

In a recent municipal water supply project, HDPE pipes were used to replace aging iron and concrete pipelines. The project involved the installation of over 50 kilometers of HDPE pipes, ranging in diameter from 100mm to 500mm. The HDPE pipes were chosen for their durability, corrosion resistance, and ease of installation. The project was completed ahead of schedule and within budget, resulting in significant cost savings. The new HDPE water supply system has reduced water loss by over 30% and improved overall system efficiency.

Industrial Water Supply System

An industrial manufacturing facility installed HDPE pipes for their process water supply system. The facility required a reliable and efficient solution for transporting large volumes of water at high pressures. HDPE pipes were selected for their ability to withstand high - pressure conditions and provide seamless, leak - proof connections. The installation of HDPE pipes resulted in a 20% reduction in pumping costs and a significant improvement in system reliability. The facility has also benefited from reduced maintenance costs and improved water quality.

Frequently Asked Questions (FAQs) About HDPE Pipes for Water Supply

Q1: Is HDPE pipe safe for drinking water?

Yes, HDPE pipes are safe for drinking water. They are made from Sanitary materials and do not leach harmful substances into the water, ensuring a safe and reliable water supply.

Q2: How long do HDPE pipes last?

Properly installed HDPE pipes can last up to 50 +years. Their long lifespan is due to their resistance to corrosion, UV degradation, and general wear and tear.

Q3: How are HDPE pipes installed?

HDPE pipes are installed using advanced heat fusion methods such as butt fusion and electrofusion welding. These methods create seamless, leak - proof connections that are as strong as the pipe itself.

Q4: Do HDPE pipes require special maintenance?

HDPE pipes require minimal maintenance. Their resistance to corrosion and environmental stress means they do not need additional coatings or treatments. Regular inspection and monitoring are recommended to ensure long - term performance.

Q5: Can HDPE pipes be recycled?

Yes, HDPE pipes are 100% recyclable. At the end of their service life, they can be fully recycled, reducing waste and promoting sustainability.

Conclusion

HDPE pipes are a superior choice for water supply systems, offering unmatched durability, corrosion resistance, and ease of installation. With a long operational lifespan and minimal maintenance requirements, HDPE pipes provide a cost - effective and sustainable solution for modern water supply systems. Akan Enterprise Group (Shanghai) Co., Ltd. is a leading provider of HDPE pipes, offering a comprehensive range of products manufactured to the highest quality standards. By choosing HDPE pipes for your water supply system, you can benefit from enhanced reliability, improved efficiency, and reduced environmental impact. Whether for municipal, residential, or industrial applications, HDPE pipes are the future of efficient and sustainable water supply systems.

Related Articles

What is a water supply pipe?

A water supply pipe is a vital component of any plumbing system, delivering clean water to homes, businesses, and industries. These pipes ensure a steady flow of potable water for drinking, cooking, cleaning, and more. Get insights on choosing the right pipes for your needs.

What Type of Pipe Is Used for Water Supply?

Ever wondered what type of pipe is used for water supply in your home or city? Choosing the right water supply pipe impacts water quality, pressure, and your wallet. From durable cement-lined ductile iron to lightweight PVC pipes, each option has its role in keeping water flowing safely. Ensure your water supply system is reliable and efficient with our detailed insights and recommendations.

CONTACT

Get in Touch With Us