Diving into the world of plumbing, you might wonder: Is PPR pipe better than PEX? This is a common question, and we’re here to help you navigate the differences. From material and cost to performance and application, this guide will provide the insights you need to make an informed choice. Whether you’re planning a home renovation or a commercial project, understanding PPR and PEX pipes can save you time and money. Let’s explore together!

Understanding PPR Pipes

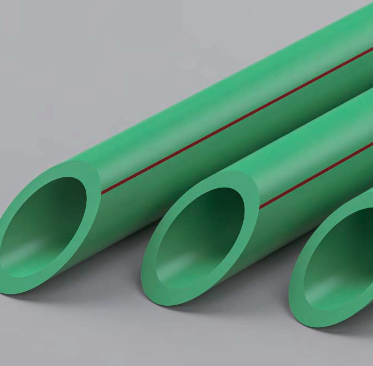

What is PPR Pipe Made of?

PPR pipes are made from polypropylene random copolymer. This material gives them high temperature resistance and durability

Key Properties and Characteristics of PPR Pipes

PPR pipes possess several key properties that make them suitable for various applications. These properties include high durability and resistance to corrosion and scale buildup.PPR pipes also have excellent chemical resistance, making them suitable for both hot and cold water applications. Additionally, they have a long lifespan and require minimal maintenance.

Typical Uses of PPR Pipes in Plumbing and Water Supply

PPR pipes are widely used in residential and commercial plumbing systems. They are ideal for domestic water supply, industrial water systems, and agricultural irrigation. PPR pipes are also commonly used in home decoration projects for water supply and drainage pipes due to their ease of installation and reliability.

Advantages of PPR Pipes

PPR pipes offer several advantages over other types of pipes. They are highly durable and can withstand high temperatures, making them suitable for hot water applications. PPR pipes are also resistant to corrosion and scale buildup, which helps to maintain a smooth flow of water and reduce the risk of leaks. Additionally, they have excellent chemical resistance, making them suitable for a wide range of applications. PPR pipes are known for their long lifespan and require minimal maintenance, making them a cost-effective choice for many plumbing needs.

Understanding PEX Pipes

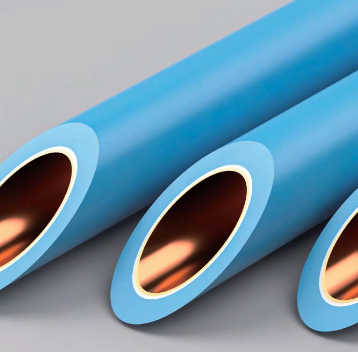

What is PEX Pipe Made of?

PEX pipes are made from cross-linked polyethylene. This material gives them increased strength and flexibility. PEX pipes can withstand high pressure and resist corrosion and scale buildup.

Key Properties and Characteristics of PEX Pipes

PEX pipes have several key properties that make them suitable for various applications. They are highly flexible and can be bent to fit different installation requirements. PEX pipes are also resistant to freezing temperatures, making them ideal for cold weather climates. Additionally, they have a long lifespan and require minimal maintenance.

Common Applications for PEX Pipes in Residential and Commercial Plumbing

PEX pipes are widely used in residential and commercial plumbing systems. They are ideal for hot and cold water supply lines, floor heating systems, and radiant heating applications. PEX pipes are also used in industrial settings for their versatility and durability.

Advantages of PEX Pipes

PEX pipes offer several advantages over other types of pipes. They are highly flexible, making them easy to install in tight spaces. PEX pipes are also resistant to freezing, which reduces the risk of bursting in cold weather. Additionally, they have excellent resistance to corrosion and scale buildup, ensuring a smooth flow of water and reducing the risk of leaks. PEX pipes are known for their long lifespan and require minimal maintenance, making them a cost-effective choice for many plumbing needs.

PPR vs PEX: Key Differences

Material Composition and Manufacturing Differences

PPR pipes are made from polypropylene random copolymer, giving them high temperature resistance and durability. PEX pipes are made from cross-linked polyethylene, which provides flexibility and strength. PPR pipes require a hot melt connection process, while PEX pipes can be connected using push-in or ferrule connections.

Temperature and Pressure Resistance Comparison

PPR pipes can handle high temperatures up to 95°C (203°F) and pressures up to 25 bar (362 psi). PEX pipes can withstand temperatures up to 93°C (200°F) and pressures up to 10 bar (145 psi). PPR pipes are better for high-temperature applications, while PEX pipes are more suitable for cold climates.

Flexibility and Installation Process: Which is Easier?

PEX pipes are highly flexible and can be bent to fit various installation requirements. They are easier to install due to their flexibility and simple connection methods. PPR pipes are more rigid and require specialized tools for hot melt connections, making installation more complex.

Chemical Resistance and Durability: How Do They Compare?

Both PPR and PEX pipes have excellent chemical resistance and are resistant to corrosion and scale buildup. PPR pipes are known for their long lifespan and durability in high-temperature applications. PEX pipes are highly durable and resistant to freezing, making them suitable for cold weather climates.

Longevity and Lifespan in Plumbing Systems

PPR pipes have a long lifespan and require minimal maintenance, making them suitable for long-term use in plumbing systems. PEX pipes are also durable and have a long lifespan, but may require more attention to connections and fittings. Both types of pipes can last for decades with proper installation and maintenance.

Environmental Impact and Recyclability

PPR pipes are made from polypropylene, which is recyclable and has a lower environmental impact. PEX pipes are also recyclable but may require more energy to produce due to the cross-linking process. Both types of pipes are environmentally friendly and can be recycled at the end of their lifespan.

| Feature | PPR Pipes | PEX Pipes |

|---|---|---|

| Material | Polypropylene random copolymer | Cross-linked polyethylene |

| Temperature Resistance | Up to 95°C (203°F) | Up to 93°C (200°F) |

| Pressure Resistance | Up to 25 bar (362 psi) | Up to 10 bar (145 psi) |

| Flexibility | Rigid | Highly flexible |

| Installation | Requires specialized tools | Easy to install |

| Chemical Resistance | Excellent | Excellent |

| Durability | Long lifespan | Long lifespan |

| Environmental Impact | Recyclable, lower impact | Recyclable, higher energy use |

By understanding these key differences, you can make an informed decision on which type of pipe is best suited for your specific plumbing needs.

Performance Comparison

Resistance to Heat and Hot Water Applications

PPR pipes excel in hot water applications. They can handle continuous temperatures up to 95°C (203°F). PEX pipes are also suitable for hot water but may soften with prolonged exposure to high temperatures. PPR pipes are preferred for systems requiring high thermal stability.

Resistance to Freezing and Bursting

PEX pipes are highly resistant to freezing. They can expand up to three times their diameter if frozen, reducing the risk of bursting. PPR pipes remain flexible down to -20°C (-4°F) but are less forgiving if frozen solid. PEX pipes are ideal for cold climates.

Pressure Ratings and Suitability for High-Pressure Systems

PPR pipes can handle pressures up to 25 bar (362 psi), making them suitable for high-pressure systems. PEX pipes are rated for pressures up to 10 bar (145 psi). PPR pipes are better for industrial applications requiring higher pressure resistance.

Resistance to Scaling and Corrosion

Both PPR and PEX pipes have smooth interiors that resist scaling and corrosion. This ensures a consistent water flow and reduces maintenance. PPR pipes are particularly noted for their long-term resistance to chemical degradation.

Impact of UV Exposure

PPR pipes are more resistant to UV exposure compared to PEX pipes. PEX pipes can degrade when exposed to sunlight for extended periods. PPR pipes are better suited for outdoor applications where UV exposure is a concern.

| Feature | PPR Pipes | PEX Pipes |

|---|---|---|

| Heat Resistance | High (up to 95°C) | Moderate (up to 93°C) |

| Freeze Resistance | Low temperature tolerance | High expansion capacity |

| Pressure Rating | High (up to 25 bar) | Moderate (up to 10 bar) |

| Scaling and Corrosion | Excellent resistance | Excellent resistance |

| UV Resistance | High | Low |

Understanding these performance differences helps in selecting the right pipe material for specific plumbing needs.

Cost Comparison

Material Cost of PPR vs PEX Pipes

PPR pipes are generally more affordable than PEX pipes. The material cost for PPR is lower, making it a cost-effective choice for many plumbing projects. PEX pipes, while more expensive, offer higher performance and durability.

Installation Cost Differences

Installation costs for PPR pipes can be higher due to the need for specialized tools and skilled labor for hot melt connections. PEX pipes are easier to install, often reducing labor costs and installation time. This makes PEX a popular choice for DIY projects.

Long-term Cost Implications

PPR pipes have a long lifespan and require minimal maintenance, reducing long-term costs. PEX pipes are durable but may require more attention to connections, potentially increasing maintenance costs over time. However, their flexibility can reduce the need for repairs in certain applications.

Availability and Regional Pricing Factors

PPR pipes are widely available and often more affordable in regions with high demand. PEX pipes may have higher upfront costs but can be more cost-effective in areas with extreme weather conditions. Regional pricing can vary based on local supply and demand.

| Feature | PPR Pipes | PEX Pipes |

|---|---|---|

| Material Cost | Lower | Higher |

| Installation Cost | Higher (specialized tools) | Lower (easier installation) |

| Long-term Costs | Minimal maintenance | Potential for higher maintenance |

| Availability | Widely available | Regionally variable |

Understanding these cost factors can help you make an informed decision based on your budget and specific needs.

Application Suitability: When to Choose PPR or PEX

Ideal Use Cases for PPR Pipes

PPR pipes are ideal for industrial and commercial applications. They are commonly used in hot water lines due to their high temperature resistance. PPR pipes are also suitable for systems requiring long-term durability and minimal maintenance.

Ideal Use Cases for PEX Pipes

PEX pipes are well-suited for residential plumbing and retrofit projects. Their flexibility makes them easy to install in tight spaces. PEX pipes are used for both cold and hot water lines, offering versatility in residential settings.

Suitability for Potable Water, Heating Systems, and Radiant Floors

Both PPR and PEX pipes are suitable for potable water systems. PPR pipes are often used in commercial potable water applications due to their durability. PEX pipes are popular in residential potable water systems and are also used in heating systems and radiant floors due to their flexibility and resistance to freezing.

Regional Climate Considerations and Impact on Pipe Choice

In regions with extreme cold climates, PEX pipes are preferred due to their resistance to freezing and bursting. PPR pipes are suitable for areas with moderate climates and high-temperature needs. Regional climate conditions play a significant role in determining the best pipe material for specific applications.Choosing the right pipe material depends on your specific needs, climate conditions, and application requirements.

| Feature | PPR Pipes | PEX Pipes |

|---|---|---|

| Ideal Use Cases | Industrial, commercial, hot water lines | Residential, retrofit, cold and hot water lines |

| Potable Water | Suitable | Suitable |

| Heating Systems | Suitable | Suitable |

| Radiant Floors | Less common | Common |

| Climate Considerations | Moderate climates | Cold climates |

FAQ

Q: Are PPR pipes safer for drinking water than PEX?

A: Both PPR and PEX pipes are safe for drinking water. PPR pipes are non-toxic and comply with international standards like NSF/ANSI 61. PEX pipes also meet these standards and are safe for potable water use.

Q: Which pipe is more environmentally friendly?

A: PPR pipes are generally more environmentally friendly. They are made from recyclable polypropylene and have a lower environmental impact compared to PEX, which requires more energy to produce due to the cross-linking process.

Q: Can PEX pipes be used outdoors?

A: PEX pipes are not ideal for outdoor use due to their low UV resistance. Prolonged exposure to sunlight can degrade PEX pipes. PPR pipes are more suitable for outdoor applications as they have better UV resistance.

Q: How do PPR and PEX compare in earthquake-prone areas?

A: PEX pipes are more flexible and can withstand movement, making them suitable for earthquake-prone areas. PPR pipes are rigid and may require additional support in such areas to prevent damage.

Q: What are the health and safety certifications for each?

A: PPR pipes comply with standards like ISO 15874 and ASTM F2389, ensuring safety for potable water. PEX pipes meet ASTM F876/F877 and ISO 15875, which also ensure safety and performance in plumbing systems.

Summary

Choosing between PPR and PEX pipes depends on your specific needs. PPR pipes are ideal for high-temperature applications and offer long-term durability, making them suitable for industrial and commercial projects. PEX pipes are flexible and easy to install, making them perfect for residential use and cold climates. Both materials are safe for drinking water and environmentally friendly. For more detailed information and personalized recommendations, contact Akan Enterprise Group (Zhejiang) Co., Ltd.

Whether you need pipes for hot water systems or cold climates, Akan Enterprise Group (Zhejiang) Co., Ltd. has you covered. Our PPR and PEX pipes are designed to meet your specific requirements, offering durability, flexibility, and long-term value. Contact us today to find the perfect solution for your plumbing needs.

Related Articles

What is a PPR Pipe ?-A Comprehensive Guide

Wondering what a PPR pipe is and why it’s gaining popularity? You’re in the right place! PPR pipes, made from Polypropylene Random Copolymer, are revolutionizing plumbing systems with their durability, efficiency, and versatility. Whether you're a homeowner or a professional, this guide has everything you need to make informed decisions about PPR pipes.

CONTACT

Get in Touch With Us