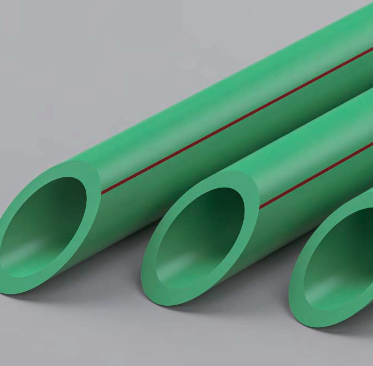

In China's residential and engineering markets, PPR pipes play a vital role in water supply systems. PPR pipes are made from random copolymer polypropylene, a non-toxic and eco-friendly material. Compared to traditional copper, cast iron, cement, or galvanized steel pipes, PPR pipes offer advantages such as environmental safety, low flow resistance, moderate cost, and long service life. Their health benefits and smooth inner walls are particularly outstanding. For example, POLYGON PPR pipes use well-known high end raw materials (Hyosung, Sabic, Borouge, etc.) for extrusion production. After heat-fusion welding, they can directly transport drinking water, ensuring household water safety. POLYGON PPR pipes feature smooth inner walls that resist scaling, maintaining unobstructed water flow and reducing resistance

.

However, some countries still prefer CPVC pipes for water supply due to their lightweight nature, ease of handling, and installation flexibility (e.g., solvent cement or threaded connections)

.

Why Did PPR Pipes Replace CPVC in China?Before the 1980s, CPVC was widely used in China. The shift occurred for several reasons:

1. Connection Reliability:

o CPVC primarily uses solvent cement socket connections, which rely on chemical adhesives. These adhesives contain toxic solvents (benzene, toluene, formaldehyde, tetrahydrofuran) and chlorinated PVC resin. Over time, the adhesive degrades, leading to leakage risks and releasing harmful gases

.

o PPR uses heat fusion welding, which creates a seamless molecular bond. This method is leak-proof, non-toxic, and safer for drinking water

.

2. Environmental and Health Policies:

o Post-1980s, China strengthened environmental regulations. PPR production requires no plasticizers, avoiding the risk of chlorine ion leaching from CPVC. Government policies promoted PPR as a safer alternative

.

3. Material Safety:

o CPVC adhesives pose health hazards, while PPR's heat fusion welding eliminates this risk, ensuring safe water supply for households.

AKAN ENTERPRISE GROUP, established in 2000, operates under the brand POLYGON Pipe. It specializes in water system products, including PPR, HDPE, UPVC, PE-Xb, PE-RT, and PB pipes and fittings.

· Certifications: Aenor, DVGW, WRAS, and CE

.

· Materials: 100% virgin raw materials from premium suppliers (Hyosung, Sabic, Borouge, Sinopec, etc.).

· Production: 6 factories and 3 CNAS-certified labs ensure fast delivery and consistent quality.

.

As health consciousness grows and building heights increase, PPR is projected to surpass CPVC in market share and growth. For high-quality PPR pipes, please contact POLYGON PIPE to get fast quotations.

In China's residential and engineering markets, PPR pipes play a vital role in water supply systems. PPR pipes are made from random copolymer polypropylene, a non-toxic and eco-friendly material. Compared to traditional copper, cast iron, cement, or galvanized steel pipes, PPR pipes offer advantages such as environmental safety, low flow resistance, moderate cost, and long service life. Their health benefits and smooth inner walls are particularly outstanding. For example, POLYGON PPR pipes use well-known high end raw materials (Hyosung, Sabic, Borouge, etc.) for extrusion production. After heat-fusion welding, they can directly transport drinking water, ensuring household water safety. POLYGON PPR pipes feature smooth inner walls that resist scaling, maintaining unobstructed water flow and reducing resistance.

However, some countries still prefer CPVC pipes for water supply due to their lightweight nature, ease of handling, and installation flexibility (e.g., solvent cement or threaded connections)

Before the 1980s, CPVC was widely used in China. The shift occurred for several reasons:

Connection Reliability:

CPVC primarily uses solvent cement socket connections, which rely on chemical adhesives. These adhesives contain toxic solvents (benzene, toluene, formaldehyde, tetrahydrofuran) and chlorinated PVC resin. Over time, the adhesive degrades, leading to leakage risks and releasing harmful gases.

PPR uses heat fusion welding, which creates a seamless molecular bond. This method is leak-proof, non-toxic, and safer for drinking water.

Environmental and Health Policies:

Click here to edit your content.

Click here to edit your content.

Q:Click here to edit your content.

A:Click here to edit your content.

Q:Click here to edit your content.

A:Click here to edit your content.

Related Articles

Which is better HDPE or PVC?

In the world of plumbing and infrastructure, selecting the right pipe material is a critical decision that can significantly impact the longevity, efficiency, and overall performance of your system. The article provides an in-depth analysis of the physical properties, installation and maintenance requirements, environmental impact, and lifecycle costs of both materials. Whether you are a civil engineer, municipal planner, or a homeowner, this guide offers valuable insights to help you make an informed decision.

What is a PPR Pipe ?-A Comprehensive Guide

Wondering what a PPR pipe is and why it’s gaining popularity? You’re in the right place! PPR pipes, made from Polypropylene Random Copolymer, are revolutionizing plumbing systems with their durability, efficiency, and versatility. Whether you're a homeowner or a professional, this guide has everything you need to make informed decisions about PPR pipes.

CONTACT

Get in Touch With Us